Precision Engineering in Aerospace and Defence: Challenges and Innovations in the UK

As you explore precision engineering in aerospace and defence, you’ll navigate complex regulatory landscapes, stringent compliance requirements, and cybersecurity threats. To stay ahead, the UK industry must prioritise innovations in materials science, additive manufacturing, and nanotechnology. Talent acquisition and retention are critical, with a focus on diversity and inclusion. Supply chain resilience strategies are essential to mitigate disruptions. As you continue, you’ll uncover the latest advancements and challenges facing the UK aerospace and defence industry, and discover how future-proofing strategies can drive innovation and growth. The landscape is complex, but the opportunities for transformation are vast.

Key Takeaways

• The UK aerospace and defence industry faces a significant skills gap, with a shortage of skilled engineers, technicians, and scientists, particularly in precision engineering.• Implementing robust compliance procedures, including regular audits, training programmes, and internal controls, is vital to mitigate risks in the industry.• Advanced materials and nanotechnology are being developed to provide unparallelled strength-to-weight ratios, revolutionising aerospace and defence applications in the UK.• Additive manufacturing and 3D printing are transforming the production of complex components in aerospace and defence, enabling the creation of lightweight, high-performance parts.• The UK industry must invest in Industry 4.0 technologies, such as Digital Twins, to reduce production costs and timelines, and stay ahead of emerging global competitors.

Regulatory Landscapes and Compliance

You must navigate a complex regulatory landscape to guaranty compliance in the aerospace and defence industries, where a single misstep can have severe consequences for national security, human life, and business reputation.

To certify compliance, you need to stay up-to-date with the latest Airworthiness Directives (ADs) issued by the European Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA). These directives outline specific requirements for the design, production, and maintenance of aircraft and aerospace components.

In addition to ADs, you must also comply with Export Controls, which regulate the export of dual-use goods and technologies. This includes verifying that sensitive information and technologies aren’t transferred to unauthorised parties, thereby protecting national security and intellectual property.

Failure to comply with these regulations can result in severe penalties, including fines, legal action, and damage to your business reputation. Moreover, non-compliance can also compromise the safety of people and the integrity of national security.

To mitigate these risks, implementing robust compliance procedures is vital, including regular audits, training programmes, and internal controls. By doing so, you can guaranty that your organisation operates within the boundaries of the regulatory landscape, minimising the risk of non-compliance and its consequences.

Talent Acquisition and Retention

As precision engineering in aerospace and defence demands rigorous compliance with stringent regulations, it also requires attracting and retaining top talent who can navigate these complexities, ensuring that innovative solutions meet the highest standards of quality and reliability.

You need experts who can design, develop, and manufacture cutting-edge systems, components, and materials that meet the exacting demands of the aerospace and defence industries.

However, the industry faces a significant skills gap, with a shortage of skilled engineers, technicians, and scientists.

This talent shortage is exacerbated by an ageing workforce, with many experienced professionals nearing retirement.

To address this challenge, companies must adopt innovative talent acquisition and retention strategies that prioritise diversity and inclusion.

Implement diversity and inclusion initiatives to attract underrepresented groups, such as women and minorities, who can bring fresh perspectives and skills to the industry.

Develop apprenticeships, interneships, and mentorship programmes to nurture emerging talent and build a pipeline of skilled professionals.

Collaborate with educational institutions to develop curricula that address the skills gap, ensuring that graduates have the skills and knowledge required by the industry.

Supply Chain Resilience Strategies

Twenty-first-century aerospace and defence supply chains must incorporate resilience strategies to mitigate the risks of disruptions, guaranteeing that critical components and materials are consistently delivered to meet the exacting demands of these industries. As you navigate the complex landscape of supply chain management, prioritise resilience to minimise the impact of disruptions on your operations.

| Resilience Strategy | Description |

|---|---|

| Risk Assessment | Identify potential risks and develop contingency plans to mitigate their impact |

| Supply Diversification | Develop relationships with multiple suppliers to reduce dependance on a single source |

| Inventory Management | Maintain strategic inventory levels to guaranty continuity of operations |

Materials Science Breakthroughs

As you explore the cutting-edge landscape of materials science, you’ll discover breakthroughs that are revolutionising aerospace and defence applications.

Advanced composite materials are being engineered to provide unparallelled strength-to-weight ratios, while smart materials are being developed to respond adaptively to changing conditions.

Researchers are pushing the boundaries of nanostructure development, harnessing new possibilities for materials with unique properties.

Advanced Compositae Materials

Advanced composite materials, crafted from a combination of reenforcing fibres and matrices, have emerged as a game-changer in aerospace and defence, boasting unparallelled strength-to-weight ratios and resistance to fatigue and corrosion.

These innovative materials have revolutionised the industry, enabling the creation of lightweight, high-performance structures that meet the demanding requirements of aerospace and defence applications.

Some of the key advancements in advanced composite materials include:

-

Fibre weaving: The development of complex fibre weaving patterns has enabled the creation of materials with unique properties, such as tailored stiffness and strength.

-

Material hierarchies: The design of hierarchical material structures has allowed for the optimisation of material properties at multiple scales, resulting in enhanced performance and efficiency.

-

Multifunctional materials: The integration of multiple functions within a single material has enabled the creation of adaptive, responsive, and self-healing materials that can respond to changing environmental conditions.

These breakthroughs have opened up new possibilities for the design and development of advanced aerospace and defence systems, enabling the creation of more efficient, sustainable, and high-performance systems.

Smart Material Applications

You’re now exploring the domain of smart material applications, a breakthrough in materials science that’s revolutionising aerospace and defence systems.

Building on the advancements in advanced composite materials, researchers have now turned their attention to harnessing the potential of smart materials, which can dynamically respond to changing environmental conditions, opening up new avenues for adaptive aerospace and defence systems.

These smart materials, such as shape memory alloys, can alter their shape or properties in response to temperature, light, or other external stimuluses.

This adaptability enables the creation of adaptive structures that can adjust to changing conditions, enhancing their performance and efficiency.

For instance, shape memory materials can be used to create morphing wings that adjust their shape to optimise aerodynamics, reducing fuel consumption and emissions.

In the defence sector, smart materials are being explored for applications such as self-healing materials that can repair damaged structures, reducing maintenance costs and downtime.

As researchers continue to push the boundaries of smart material applications, you can expect to see significant advancements in the development of adaptive aerospace and defence systems that can respond to emerging threats and challenges.

Nanostructure Development

Researchers have made significant strides in nanostructure development, tapping into the potential for materials with unprecedented strength, conductivity, and optical properties that can revolutionise aerospace and defence applications.

You’re likely to benefit from these advancements, as they enable the creation of ultra-lightweight yet incredibly strong materials for aircraft and spacecraft. These breakthroughs also open up opportunities for novel sensing and communication technologies.

Some key areas of progress include:

-

Nano Fabrication: Techniques like molecular beam epitaxy and atomic layer deposition allow for precise control over material composition and structure, enabling the creation of tailored nanostructures with unique properties.

-

Molecular Assembly: Scientists are developing methods to assemble molecules into precise patterns, enabling the creation of materials with specific optical, electrical, and mechanical properties.

-

Nanostructure Characterisation: Advanced imaging and spectroscopy techniques are being used to study the properties of nanostructures, providing valuable insights for their optimisation and integration into aerospace and defence systems.

These advancements hold immense potential for transforming the aerospace and defence industries.

As you explore the possibilities of nanostructure development, you’ll uncover new opportunities for innovation and growth.

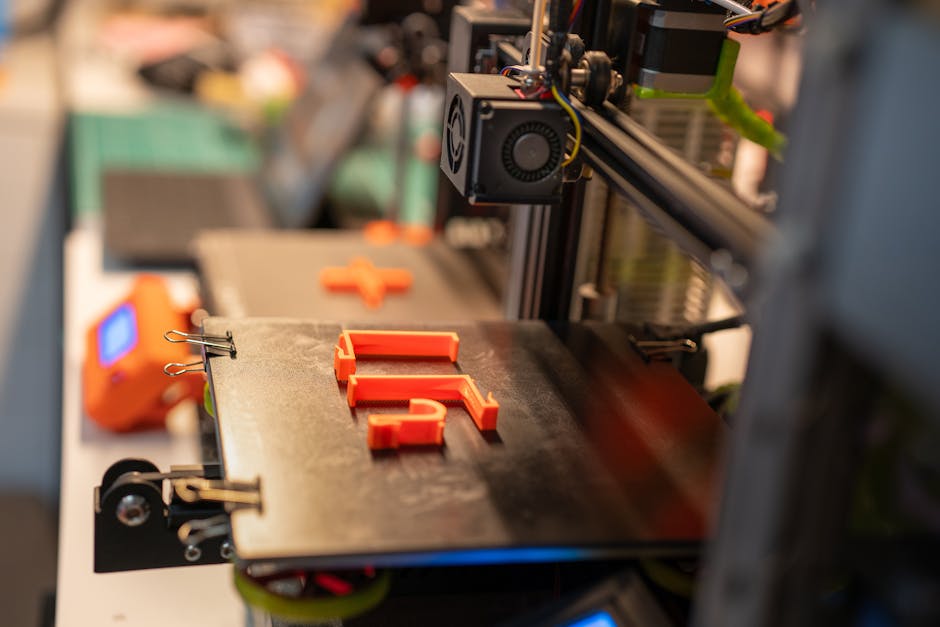

3D Printing and Additive Manufacturing

In the aerospace and defence industries, additive manufacturing (AM) has revolutionised the production of complex components, enabling the creation of lightweight, high-performance parts with unprecedented precision. You’re now able to produce complex geometries and internal structures that were previously impossible to manufacture using traditional methods. AM’s design flexibility allows you to optimise part performance, reduce material waste, and minimise assembly requirements.

However, material limitations still pose a significant challenge. You’re limited by the availability of suitable materials that meet the high-performance requirements of aerospace and defence applications. Currently, only a few materials, such as titanium and advanced polymers, are suitable for AM production.

| Material | Properties | Applications |

|---|---|---|

| Titanium | High strength-to-weight ratio, corrosion-resistant | Aerospace structural components, engine parts |

| Advanced Polymers | High temperature resistance, chemical resistance | Aerospace components, missile guidance systems |

| Copper | High thermal conductivity, electrical conductivity | Aerospace heat exchangers, electrical components |

| Inconel | High temperature resistance, corrosion-resistant | Aerospace engine components, heat shields |

| Aluminium | High strength-to-weight ratio, corrosion-resistant | Aerospace structural components, aircraft skins |

As you explore the potential of additive manufacturing in aerospace and defence, you’ll need to balance design flexibility with material limitations. By understanding the capabilities and limitations of each material, you can harness the full potential of AM and create innovative solutions that meet the demanding requirements of these industries.

Nanotechnology in Aerospace

As the aerospace industry continues to push the boundaries of innovation, nanotechnology is emerging as a key enabler of next-generation materials and systems.

You’re likely aware that nanotechnology involves the manipulation of matter on a molecular scale, and its applications in aerospace are vast. From enhancing the strength-to-weight ratio of materials to improving the efficiency of energy storage systems, nanotechnology is poised to revolutionise the industry.

Some of the most promising applications of nanotechnology in aerospace include:

-

Nano coatings: These ultra-thin coatings can be engineered to provide enhanced thermal insulation, reduced friction, or even self-healing properties. Imagine an aircraft with a nano-coated surface that can repair minor scratches and damages autonomously!

-

Quantum dots: These tiny crystals have unique optical properties that make them ideal for advanced sensing and imaging applications. You might see quantum dots used in next-generation navigation systems or advanced threat detection systems.

-

Nanostructured materials: By engineering materials at the nanoscale, researchers can create materials with unprecedented strength, toughness, and resistance to fatigue. These materials could be used to create lighter, stronger aircraft structures or more efficient propulsion systems.

As you explore the potential of nanotechnology in aerospace, you’ll discover a vast landscape of possibilities waiting to be explored. From advanced materials to innovative sensing technologies, the future of aerospace engineering is being shaped by the power of nanotechnology.

Cybersecurity Threats and Mitigation

As you navigate the complex landscape of precision engineering in aerospace and defence, you’re likely aware that cybersecurity threats are a pressing concern.

You’re tasked with protecting sensitive information and systems from a multitude of threats, including nation-state actors, insider threats, and advanced persistent threats.

To mitigate these risks, you’ll need to understand the threat vectors and actors, secure your communication networks, and assess supply chain risks.

Threat Vectors and Actors

You face a multitude of threat vectors and actors in the aerospace and defence industries, where a single breach can have devastating consequences. The stakes are high, and you must understand the threats you’re up against.

In this landscape, you’re not just fighting against external enemies; you’re also battling internal threats. Insider threats, for instance, can be particularly damaging, as they often have access to sensitive information and systems.

Some of the key threat vectors and actors you need to be aware of include:

-

Nation state actors: These are highly sophisticated hackers backed by nation-states, with the resources and expertise to launch targeted attacks on your systems.

-

Insider threats: These can be current or former employees, contractors, or partners who’ve access to your systems and data, and may use this access for malicious purposes.

-

Advanced Persistent Threats (APTs): These are highly targeted attacks, often sponsored by nation-states, that are designed to evade detection and persist on your systems for extended periods.

Secure Communication Networks

In aerospace and defence, secure communication networks are the lifeline of operations, and their compromise can have catastrophic consequences, making it essential to understand the cybersecurity threats and mitigation strategies to protect them.

As you venture into the world of secure communication networks, you’ll realise that the stakes are high, and the threats are multifaceted. Cybercriminals, nation-states, and insider threats can exploit vulnerabilities in your systems, putting sensitive information and national security at risk.

To mitigate these threats, you need to stay ahead of the curve.

Satellite encryption, for instance, can provide an additional layer of security for your communication networks. By encrypting data transmitted via satellites, you can prevent unauthorised access and confirm that sensitive information remains confidential.

Furthermore, the use of quantum keys can enhance the security of your communication networks. Quantum keys leverage the principles of quantum mechanics to create unbreakable encryption, making it virtually impossible for hackers to intercept and decode your data.

Supply Chain Risks

Your supply chain is only as secure as its weakest link, and the integration of third-party components can introduce vulnerabilities that hackers can exploit to compromise your entire operation. Cybersecurity threats are exacerbated by geopolitical uncertainty, border disruptions, and the complexity of modern supply chains.

As a result, it’s vital to identify and mitigate risks throughout your supply chain.

To minimise the risk of cyber-attacks, consider the following strategies:

Conduct thorough vender assessments: Evaluate the cybersecurity posture of your suppliers and partners to verify they meet your organisation’s security standards.

Implement a multi-layered defence: Use a combination of security controls, such as firewalls, intrusion detection systems, and encryption, to protect your supply chain from cyber threats.

Establish incident response plans: Develop and regularly test response plans to quickly respond to and contain cyber-attacks, minimising the impact on your operation.

Future-Proofing the UK Industry

Britain’s aerospace and defence industry must prioritise strategic investments in research and development to stay ahead of emerging global competitors and future-proof its position as a leading manufacturing nation.

You can’t afford to lag behind in embracing Industry 4.0 technologies, such as Digital Twins, which enable real-time simulation and testing, reducing production costs and timelines. To bridge the Skills Gap, you need to facilitate Knowledge Transfer between academia, industry, and government. This will guaranty that your workforce is equipped with the necessary skills to operate and maintain advanced manufacturing systems.

As you look to the future, developing a thorough Industrial Policy that promotes Economic Diversification is vital. This will enable the industry to adapt to changing market demands and capitalise on emerging opportunities. You must also prioritise investments in research and development, focussing on cutting-edge technologies that can drive innovation and growth.

To stay competitive, you need to harness the power of data analytics, artificial intelligence, and the Internet of Things (IoT) to optimise production processes and improve product design. By doing so, you’ll be well-positioned to capitalise on the opportunities presented by the fourth industrial revolution and maintain the UK’s position as a leading aerospace and defence manufacturing nation.

Conclusion

As you navigate the complex landscape of precision engineering in aerospace and defence, the UK’s future hangs in the balance.

Like a precision-crafted engine, every component must aline perfectly to drive progress. Regulatory compliance is the spark plug, talent acquisition is the fuel, and supply chain resilience is the chassis.

With materials science breakthroughs, 3D printing, and nanotechnology, the industry is poised to soar.

But cybersecurity threats lurk, waiting to disrupt the entire system.

The fate of the UK’s aerospace and defence industry hangs precariously, a delicate balance of innovation and risk.

Contact us to discuss our services now!